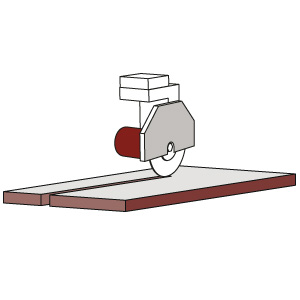

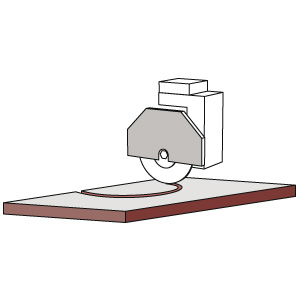

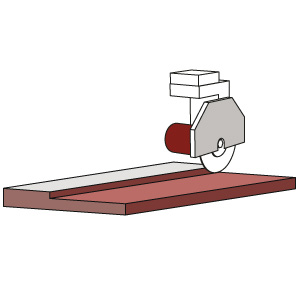

Helios Dea is а revolutionary bridge saw and machining center with 5 interpolated

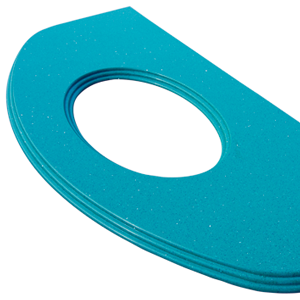

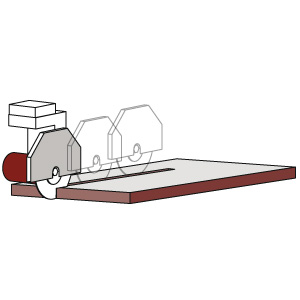

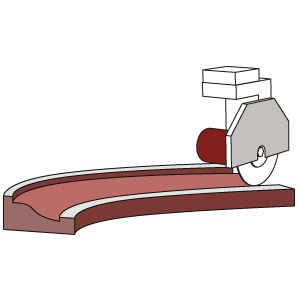

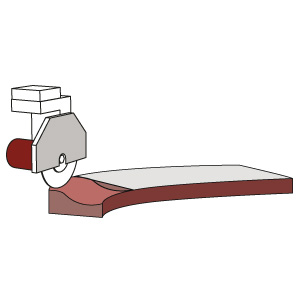

axis (8 with the Robo-Move system). It is powerful, fast, precise, and reliable; ideal for all types of cut (straight, curved, angled, etc) and manufacturing of complex frames with disk or milling tool. It is very easy to use thanks to the software, developed by Helios Automazioni and to the possible accessories. The Robo-Move system, equipped on Helios Dea, carries out all the functions of handling, clamping, and unloading of the pieces in total automation and execution speed.

Thanks to the several precautions, that make the entire process automatic and safe for the operator, Helios Dea can represent the safest and the most precise machine among the stone market.

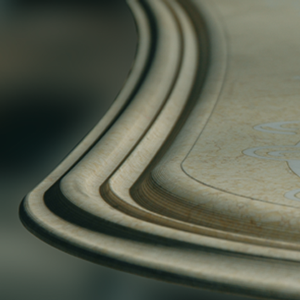

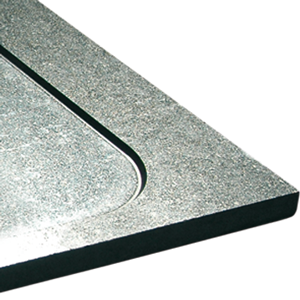

| Stainless steel structure | Thanks to the stainless steel coated structure, Helios Dea is a sturdy machine, that preserves its quality over the time; |

|---|---|

| Precision and reliability | The use of recirculating ball screws and zero backlash gears makes the machine’s movements extremely precise, thus producing highly detailed works; |

| High-quality electronics | The electronic components of Helios Dea have got CE and UL/CSA certifications, important quality indicators; |

| High frequency inverter | Thanks to the use of high frequency inverter, that provides only the necessary power for the mechanical efficiency, there are no wastes of energy, and the maximum energy saving is guaranteed; |

| Security doors | The security doors have got a manual sliding system with automatic machine stopping sensor in case of opening; |

| Laser marker | The device shows in advance the passage of the disk, indicating the correct position of the cut; |

| Xtouch - Galaxy Stone software | Helios Dea is managed by the Xtouch and Galaxy Stone software, that allow to use the machine like a bridge saw or a machining center; |

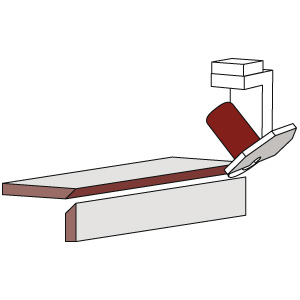

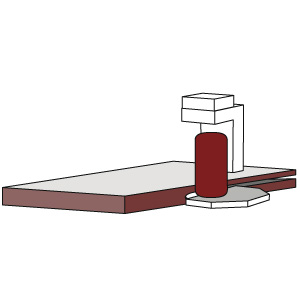

| Tilting table | The tilting table, with the Easy load solution, ensures the loading of any type of slab with the minimal effort; |

| Command consolle | The command consolle includes everything you need to control the machine: the touch screen display, the mouse, the keyboard, the command buttons, and the joystick. It is possible to use the machine remotely thanks to the portable consolle; |

| Presetting Cut system | The Presetting cut system makes DEA always ready to use, without any possibility of error; |

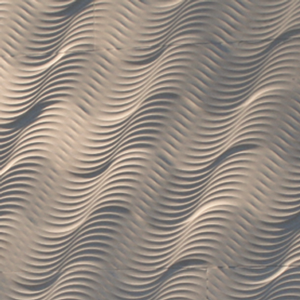

| Continuous rotation W axis | The continuous rotation of the W axis ensures the maximum speed in the creation of curved cuts. The disk works in continuous interpolation until completion, and it never gets up; |

| Robo-Move system | The revolutionary interpolated Robo-Move system allows interpolated movements, but independent from the cutting head, ensuring maximum fluidity and three time speed,compared to the classic suction cups positioned on the head. |

| Dea | |

|---|---|

| Overall dimensions | 253,94 x 137,79 x 135,83 in |

| Working area | X134,64 - Y78,74 - Z22,83 in |

| W axis rotation | 0° - Unlimited |

| A axis rotation | from 0° - to 90° |

| Motor power | 10 kW (optional 13 kW) |

| Speed movement X axis | 1377,95 in/min |

| Speed movement Y axis | 1377,95 in/min |

| Speed movement Z axis | 393,70 in/min |

| Table dimensions | 129,92 x 78,74 in |

| Spindle rotation speed | 0 - 7250 RPM |

| Tool holder cone | ISO BT 40 (only for electospindle 13 kW) |

| Installed power | 18 kW |

| Power supply | 400 Volt (3P + N + GND) 50/60 Hz |

| Net weight | 10802,65 lb |

| Disk diameter | min. 13,78 in - max. 24,61 in |

| Max. cutting depth | 7,87 in (24,61 in disk) |

| Disk-table distance | 16,34 in (24,61 in disk) |

| Disk hole diameter | 1,97 in |

| Disk locking flange diameter | 8,46 in |

| Aluminium rectified table | Tilting table with Easy-load system |

| 13 kW ISO 40 electric spindle | Lathe |

| Stainless steel structure for the lathe positioning behind the working table | Tools resetting and flatness control device |

| Explorer laser 3d for model detecting | Sacred art equipment |

| Photoscan | Robo-Move system |

| Template reader | Y extra travel |

| Virtual Stone Gallery |