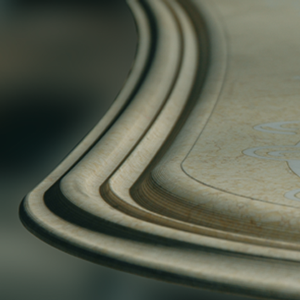

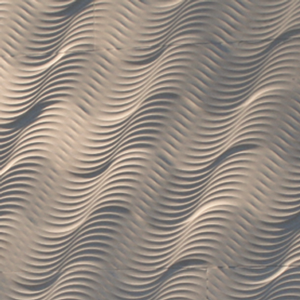

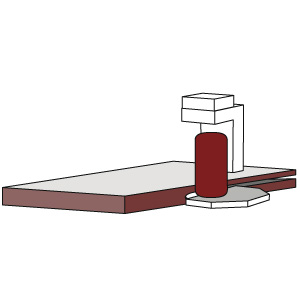

Helios Five is an extremely precise 5-axis machining center and bridge saw (6 axes with the lathe), with automatic tool change and magazine, that can be extended according to specific needs. The possible configurations make the machine suitable for the execution of important works, from roughing to finishing, with highly detailed results. The precision of the Helios Five allows to achieve the greatest part of the stone processes possible, such as small and large sculptures and statues, kitchen tops with profiling and edge polishing, drain boards and much more. This feature makes Helios Five unique in its category.

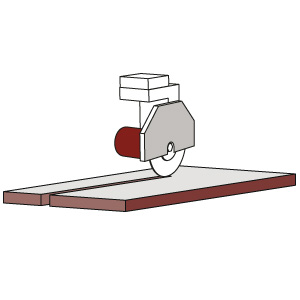

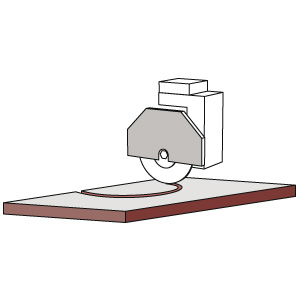

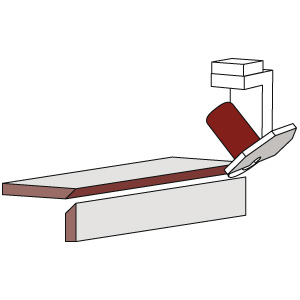

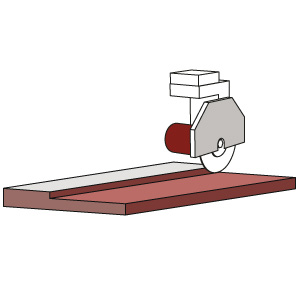

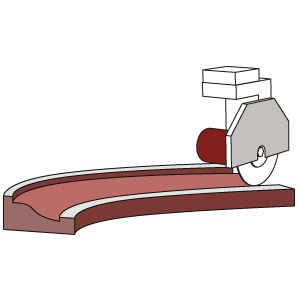

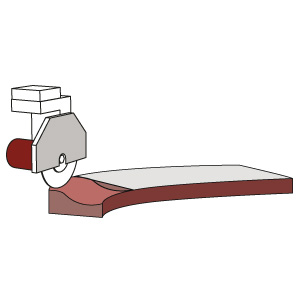

As a bridge saw, the machine can work with disks with diameters of up to 725 mm. Thanks to its imposing structure and the technology developed by Helios. Helios Five can process all types of cut with extreme precision (45° angled cuts, shaped cuts, arches cuts angled on both sides etc…)

Helios Five can have the Z stroke of 680, 1000 or 1200 mm and can be equipped with the interpolated lathe, thus increasing the executable machining in the stone sector.

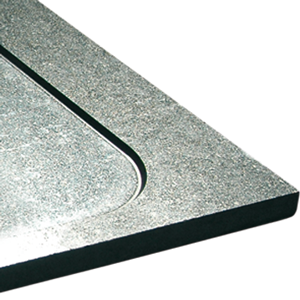

| Stainless steel structure | Thanks to the stainless steel coated structure, Helios Dea is a sturdy machine, that preserves its quality over the time; |

|---|---|

| Precision and reliability | The use of recirculating ball screws and zero backlash gears makes the machine’s movements extremely precise, thus producing highly detailed works; |

| High-quality electronics | The electronic components of Helios Dea have got CE and UL/CSA certifications, important quality indicators; |

| High frequency inverter | Thanks to the use of high frequency inverter, that provides only the necessary power for the mechanical efficiency, there are no wastes of energy, and the maximum energy saving is guaranteed; |

| Security doors | The security doors have got a manual sliding system with automatic machine stopping sensor in case of opening; |

| Laser marker | The device shows in advance the passage of the disk, indicating the correct position of the cut; |

| Xtouch - Galaxy Stone software | Helios Dea is managed by the Xtouch and Galaxy Stone software, that allow to use the machine like a bridge saw or a machining center; |

| Aluminium rectified table | The aluminium rectified table guarantees the integrity of the table and a total resistance to the processes stress and to corrosion. The calibration, performed directly by the machining center, ensures the perfect flatness of the support surface. The rectified table and the separated slats offer the possibility to set the pieces easily; |

| Tilting table | The tilting table, with the Easy-load solution, ensures the loading of any type of slab with the minimal effort; |

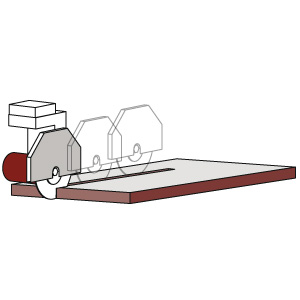

| Automatic tool change and tools magazine | Helios Five with automatic tool change manages all the machining center functions. The magazine, containing several tools ensures the maximum versatility in the tools choice. Its capacity can be modified according to specific needs; |

| Command consolle | The command consolle includes everything you need to control the machine: the touch screen display, the mouse, the keyboard, the command buttons, and the joystick. It is possible to use the machine remotely thanks to the portable consolle; |

| Robo-Move system | The revolutionary interpolated Robo-Move system allows interpolated movements, but independent from the cutting head, ensuring maximum fluidity and three time speed,compared to the classic suction cups positioned on the head. |

| Five | Five 1000 | Five 1200 | |

|---|---|---|---|

| Overall dimensions | 263,78 x 185,04/248,03 x 155,71 in | 263,78 x 185,04/248,03 x 184,92 in | 263,78 x 185,04/248,03 x 192,91 in |

| Area di lavoro | X145,67 - Y88,58/153,54 - Z26,77 in | X145,67 - Y88,58/153,54 - Z39,37 in | X145,67 - Y88,58/153,54 - Z47,24 in |

| W axis rotation | 0° - 360° | 0° - 360° | 0° - 360° |

| A axis rotation | 0° - 90° | 0° - 90° | 0° - 90° |

| Power Spindle | 15 kW | 15 kW | 15 kW |

| X axis speed movement | 1377,95 in/min | 1377,95 in/min | 1377,95 in/min |

| Y axis speed movement | 1377,95 in/min | 1377,95 in/min | 1377,95 in/min |

| Z axis speed movement | 393,70 in/min | 393,70 in/min | 393,70 in/min |

| Table dimensions | 118,11 x 78,74 in | 118,11 x 78,74 in | 118,11 x 78,74 in |

| Spindle rotation speed | 0 - 7000 RPM | 0 - 7000 RPM | 0 - 7000 RPM |

| Tool holder cone | ISO BT 40 | ISO BT 40 | ISO BT 40 |

| Operating pressure | 25 kW | 25 kW | 25 kW |

| Power supply | 400 V (3P + N + GND) 50/60 Hz | 400 V (3P + N + GND) 50/60 Hz | 400 V (3P + N + GND) 50/60 Hz |

| Disk diameter | min. 19,68 in - max. 285,4 in | min. 19,68 in - max. 285,4 in | min. 19,68 in - max. 285,4 in |

| Max. cutting depth | 9,05 in (28,54 in disk) | 9,05 in (28,54 in disk) | 9,05 in (28,54 in disk) |

| Disk hole diameter | 3,74 in | 3,74 in | 3,74 in |

| Tilting table with Easy-load system | Lathe |

| Stainless steel structure for the lathe positioning behind the working table | Tools resetting and flatness control device |

| Laser pointer for the suction cups setup | Explorer laser 3d for model detecting |

| Template reader | Y extra travel |

| Extra tools magazine | Heavy carpentry lateral structure |

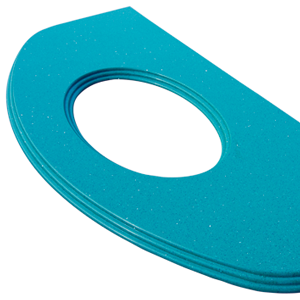

| Sacred art equipment | Tops and drain boards equipment |

| Edge polishing equipment | Laser marker |

| Photoscan | Virtual Stone Gallery |