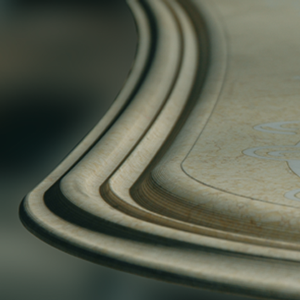

HELIOS SEVEN is a machining center of the latest generation, developed to answer the requests of the most demanding stone fabricators. The whole stainless steel structure has been conceived to pursue an unlimited durability over the time. The use of recirculating ball screws and zero backlash gears makes the machine’s movement of the axes very fluid, thus guaranteeing a highly detailed finished product.

Thanks to the use of high frequency inverter , which supplies only the necessary power for the mechanical efficiency, the maximum energy saving is ensured because there are no energy waste.

The Galaxy Stone Software manages the machining center Helios Seven and optimizes all the functions of the machine from the cut with the disk or with the tool to the edge polishing, writing, sculpturing, turning, skene, inlays, shallow kerfs for the rodding technique, and much more.

The Galaxy Stone software can manage the multiple interpolation of the axes, the tool change, the flatness control of the slabs, the template reading from the camera and all the devices, which can equipped on Helios Seven without any other integrated software.

Helios Seven has been designed to satisfy several needs, that is why there are various customizations, which allow the partial or the total automation of the process.

Helios Seven can be equipped with a 3 axes head, with a 5 axes head or with both heads in the version “Total station” for a total automated process.

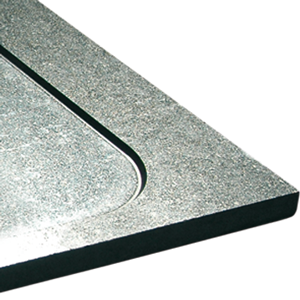

| Monolithic stainless steel structure | Thanks to the monolithic stainless steel structure, Helios Seven is a sturdy machine, that preserves its quality over the time; |

|---|---|

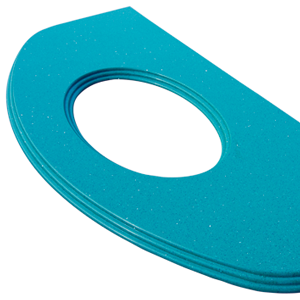

| Aluminium rectified table | The aluminium rectified table guarantees the integrity of the table and a total resistance to the processes stress and to corrosion; |

| Security doors | The front security doors have got a manual sliding system with automatic machine check sensor in case of opening; |

| Automatic tool change | Automatic tool change and tools magazine with 60 positions; |

| Command consolle | The command consolle includes everything needed to control the machine: the touch screen display, the mouse, the keyboard, the command buttons and the joystick; |

| Galaxy Stone software | The Galaxy Stone software offers many functions that allow to achieve all the typical works of the interior design, sacred art, kitchen/bath tops, obtaining excellent results on all kind of materials; |

| Sacred art equipment | The sacred art package includes all the applications necessary to process the typical works of the sacred art: inlaid / relief / engraved lettering, sculptural fonts, bas-relief, frames, drilling patterns for bronze letters, 3D floors, all certified Windows fonts, sacred images, and much more; |

| Tops and drain boards equipment | This customization allows to process kitchen and bathroom tops very quickly with an excellent product finishing, thanks to the integrated section of the software. |

| Seven | |

|---|---|

| Overall dimensions | 228,35 x 228,35 x H98,42 in |

| Axis stroke | X132,67 - Y118,11 - Z12,79 in |

| Compressed air | Min. 7 bar |

| Power supply | 400 V (3P+N+GND) 50/60 Hz |

| Installed power | 16 kW |

| Spindle rotation speed | 0-9.000 rpm |

| Tool holder | ISO BT 40 - 1/2" GAS - H7 |

| Spindle power | 7,5 HP - 3 HP |

| Tool magazine | Max. 60 positions |

| Max working speed | 1377,95 in/min |

| Bridge passing | 21,06 in - 39,37 in |

| Water consumption | 40 L/min |

| Net weight | 8818,49 lb |

| Extra tools magazine | Inclined draining boards device |

| Tools resetting and flatness control device | Gearbox option for straight cutting with disk and for columns’ grinding |

| Laser pointer for the suction cups setup | Gearbox option for frontal sculptures |

| Explorer laser 3d for model detecting | Gearbox option for cutting with convex disk |

| Template reader |