Helios Lux is the fastest and most efficient bridge polishing machine with automatic tool change in the market. It can polish all materials (granite, onyx, quartz, etc.) with excellent results, thanks to the technology developed by Helios Automazioni.

The innovation lies both in the machine’s head, with some mechanisms that control the pressure and keep it constant, and in the software, with the possibility to work many materials automatically thanks to specific functions.

Furthermore, with the camera for the detection of the slabs, starting a polishing cycle becomes an extremely simple operation

| Stainless steel structure | Thanks to the stainless steel, from the fixing bolts to the structure, Helios Lux is a sturdy machine, that preserves its quality over the time; |

|---|---|

| Precision and reliability | The use of recirculating ball screws makes the machine’s movements extremely precise, thus producing highly detailed works; |

| High-quality electronics | The electronic components of Helios Lux have got CE and UL/CSA certifications, important quality indicators; |

| Automatic tool change and tools magazine | With the Helios Lux automatic tool change, it is possible to polish every material without the manual intervention. The tools magazine, with several abrasives, has got 5 positions and it is on the side part in order to reduce the overall dimensions, thus optimising the useful working area. It is possible to increase the tools magazine to 12 positions |

| Xtouch software | Helios Lux is managed by the Xtouch software, which allows to polish a wide range of materials automatically, thanks also to the interaction of the PhotoScan; |

| Command consolle | The command consolle includes everything needed to control the machine: the touch screen display, the mouse, the keyboard, the command buttons, and the joystick. It is possible to use the machine remotely thanks to the portable consolle. |

| Lux | |

|---|---|

| Overall dimensions | 212,60 x 127,95 x 96,46 in |

| Working area | X129,92 - Y78,35 - Z12,80 in |

| X axis stroke | 139,37 in |

| Y axis stroke | 78,35 in |

| Z axis stroke | 12,80 in |

| Motor power | 7,5 kW |

| X axis speed movement | 1377,95 in/min |

| Y axis speed movement | 787,40 in/min |

| Z axis speed movement | 590,55 in/min |

| Table dimensions | 129,92 x 78,74 in |

| Spindle rotation speed | 0 - 2400 RPM |

| Installed power | 10 kW |

| Power supply | 400 Volt (3P + N + GND) 50/60 Hz |

| Tool changer | Automatic |

| Tools magazine | 5 positions |

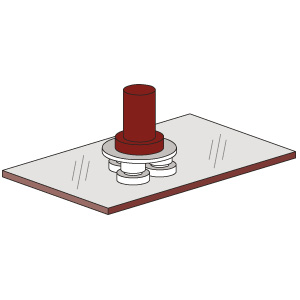

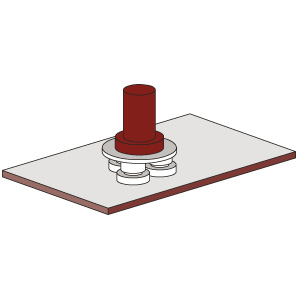

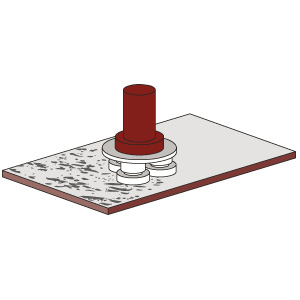

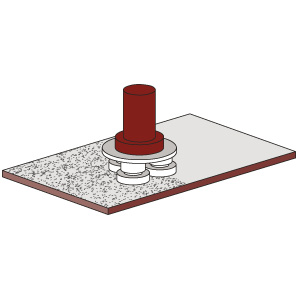

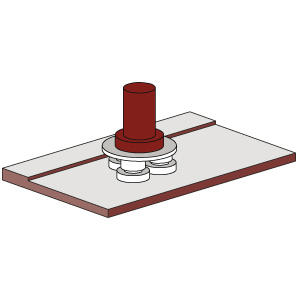

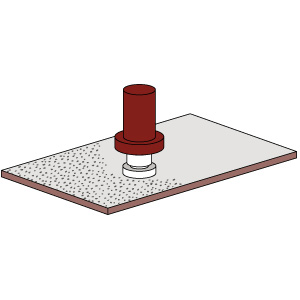

| Tilting table with Easy-load system | PhotoScan |

| Extra tools magazine | Calibrating |

| Sandblasted effect |